Description

Control over environmental factors in poultry farms, whether open or closed, is the key to successful breeding, regardless of the type and age of the poultry.

One of the most critical systems that should be controlled around the clock is the ventilation system, responsible for ensuring clean air. The volume, speed, and direction of air entering and exiting the barn control other environmental elements, such as air purity, temperature, humidity, and coolness inside the barn. The ventilation system is also responsible for providing heat using heaters or coolness using humidification panels when needed.

In open barns, ventilation relies primarily on the breeder’s experience, involving the opening and closing of windows or curtains at appropriate times and according to the prevailing weather. However, this reliance often leads to poor results due to the inability to control exceptional and unexpected weather factors, along with the absence of a stable scientific reference on the farm.

In closed barns, various automated ventilation systems exist. The success of these systems depends significantly on the complete closure of the barn and the level of insulation. The tighter the closure and insulation, the more effective the ventilation, heating, and cooling systems are, ensuring high biosecurity.

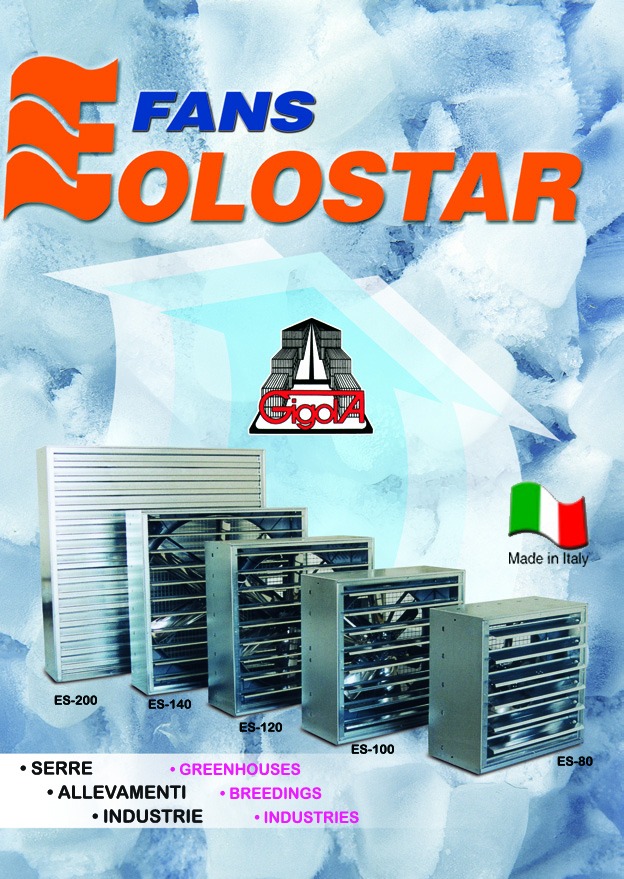

The ventilation system in closed barns consists of fans (air extractors), humidification panels, and the necessity of having ventilation openings on the sides of the barn to continuously secure fresh air, ensuring the minimum ventilation requirements for the birds. All these components are semi-automatic or automatic, allowing for controlled ventilation.

Reviews

There are no reviews yet.